Servers, GPUs, FPGAs and other semiconductors operate at increasingly high energy densities and in ever smaller packaging.

The challenge of cooling with dielectric fluid immersion has been the lack of purpose engineered coolants that are easy to use and safe for the general user and environment.

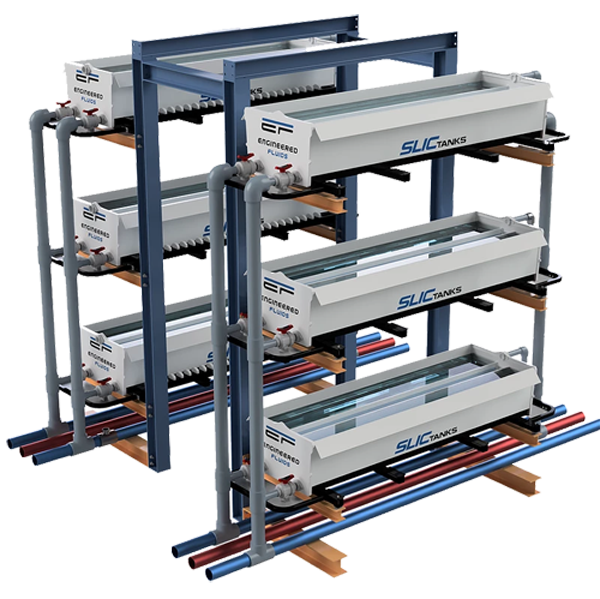

Single-phase, Liquid Immersion Cooling (SLIC) is the most effective way to manage, remove, and control waste heat for electronics.

Full immersion Cooling of electronics in Engineered Fluids Dielectric Coolants is the simplest and most reliable way of ensuring that semiconductors and electronics remain at their optimum operating temperatures without the need to use fans, complex designs, and the limitations of air as a cooling medium.

The challenge of cooling with dielectric fluid immersion has been the lack of purpose engineered coolants that are easy to use and safe for the general user and environment.

This was further complicated by the need to ensure and warranty material compatibility with the immersed components and coolants while ensuring the operational health and safety of personnel, and eliminating any negative environmental impacts posed by the coolants' manufacture and use.

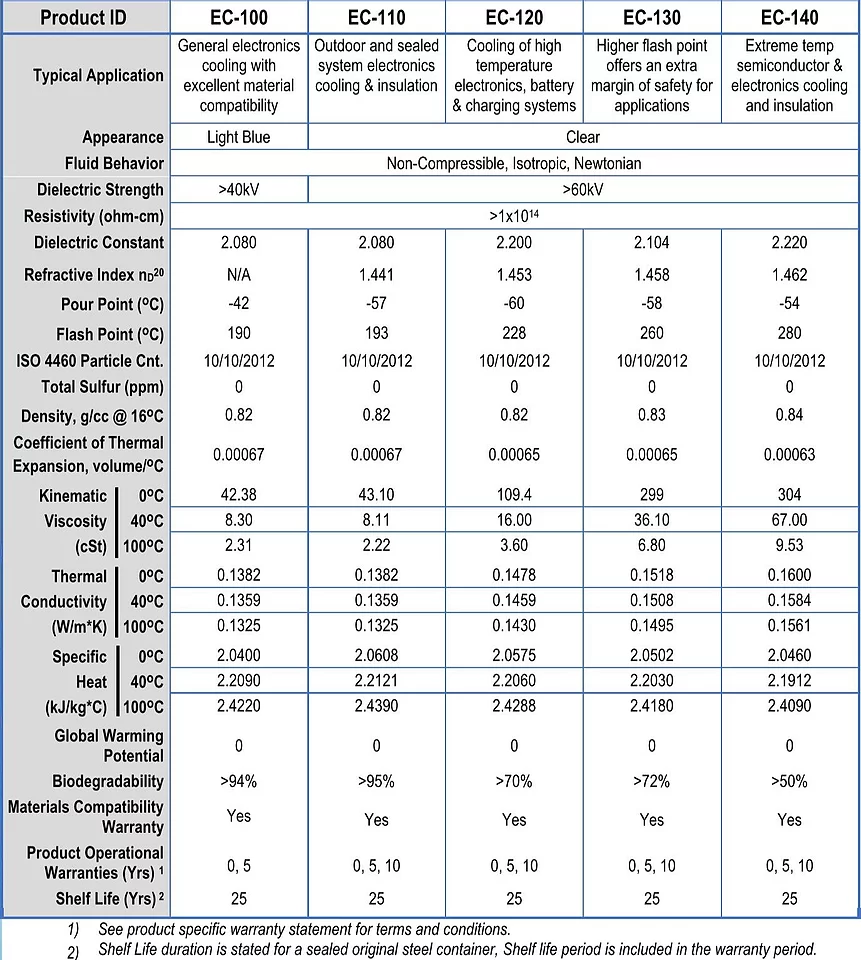

Engineered Fluids' ElectroCool Dielectric Coolants effectively solve all these challenges. ElectroCool Dielectric Coolants are 98% biodegradable, non-toxic, non-halogenated, food grade and 100% ozone safe.

In addition, the use and manufacture of ElectroCool Dielectric Coolants release no toxic waste or vapors into the workplace or environment, making Engineered Fluids' ElectroCool coolants easy to transport, use and clean up.